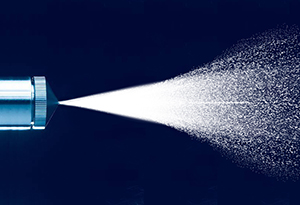

Industry Leader in Spray Drying Technologies

Particle Dynamics boasts one of the largest aqueous-based pharmaceutical spray drying facilities in North America. In 2014, Particle Dynamics invested in a new spray drying equipment capable of producing thousands of tons of product per year. Designed for flexible, multi-purpose production, the facility works seamlessly with our R&D group who have laboratory and pilot scale units ideally suited for new applications development. Based in Seymour, Indiana, USA, our production facility operates to full pharma GMPs and has been FDA inspected. We operate to US FDA 21 CFR Part 210/211, 110/111, 117 and EU drug certification standards.

Spray Drying – Applications:

Our spray drying expertise is used to control critical powder characteristics that results in key enhancements to the final dosage form including:

- Taste masking

- Improved mouthfeel

- Better dissolution/disintegration/bioavailability

- Enhanced compression characteristics increasing speed of formulation

Key products and markets:

- Directly compressible products such as Calcium Carbonate and Magnesium Carbonate

- Various vitamin and mineral products requiring highly functional characteristic

- Customized excipients

Spray Drying – Key Facts:

- Location: Seymour, Indiana, USA

- Fully automated Clean-in-Place (CIP) system

- Compliance: Complies with US FDA 21 CFR Part 210/211, 110/111, 117 and EU drug certification standards

- Standard Products:

- Destab™ Calcium Carbonate and Destab™ Magnesium CarbonateCustom Products: Excipients, Vitamins/Minerals, Pharma Rx and OTC.